Introduction to Bullet Manufacturing

Bullet manufacturing is a crucial process in the firearms industry, as it involves the production of ammunition, an essential component for any firearm. Understanding the process of bullet manufacturing is vital for both manufacturers and enthusiasts alike, as it ensures the reliability and performance of the ammunition. In this comprehensive guide, we will delve into the various stages of bullet manufacturing, from raw materials to the finished product, exploring the intricate details that go into creating high-quality bullets.

Raw Materials and Components

The first step in bullet manufacturing is acquiring the necessary raw materials and components. The primary materials required are:

- Brass Casings: Brass is the most commonly used material for bullet casings due to its durability, corrosion resistance, and ease of reloading. These casings are typically manufactured separately and supplied to bullet manufacturers.

- Primer: The primer is a small cup-shaped component that ignites the propellant when struck by the firing pin. It is composed of an impact-sensitive chemical compound.

- Propellant: Propellant, also known as gunpowder, is a mixture of chemicals that produces gas when ignited, propelling the bullet forward.

- Projectile (Bullet): The projectile, or bullet, is the component that is fired from the firearm. It can be made from various materials, including lead, copper, or specialized alloys, depending on the intended use.

- Lubricants: Lubricants are applied to the bullet and casing to reduce friction during the manufacturing process and when the bullet is loaded into the firearm.

Bullet Manufacturing Process

The bullet manufacturing process can be divided into several key stages:

1. Casing Preparation

- Cleaning and Inspection: Brass casings are thoroughly cleaned to remove any impurities or residue. They are then inspected for defects and sorted based on quality.

- Priming: The primers are inserted into the casings using specialized machinery. This process ensures precise placement and consistency.

2. Propellant Loading

- Measuring and Filling: Precise amounts of propellant are measured and filled into the casings. This step requires accuracy to ensure consistent performance.

- Sealing: The propellant is sealed within the casing to prevent any leakage or contamination.

3. Bullet Assembly

- Projectile Selection: Bullets of the desired size and material are chosen for assembly.

- Lubrication: The projectiles are lubricated to reduce friction during the loading process.

- Seating and Crimping: The lubricated projectiles are seated into the casings, and the casings are crimped to secure the bullet in place.

4. Quality Control

- Inspection and Testing: Each assembled bullet undergoes rigorous inspection to ensure it meets the required standards. This includes checking for proper seating, crimping, and overall quality.

- Function Testing: A sample of bullets is fired to test their performance and accuracy. This step ensures the ammunition functions reliably in various firearms.

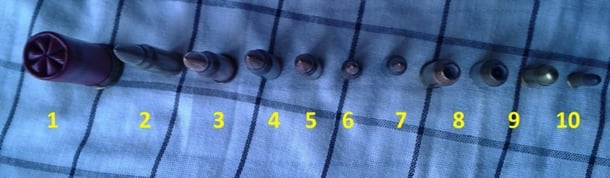

Types of Bullets

There is a wide variety of bullet types, each designed for specific purposes and firearms. Some common types include:

- Full Metal Jacket (FMJ): FMJ bullets have a lead core encased in a copper jacket, providing good penetration and accuracy. They are commonly used for target practice and training.

- Jacketed Hollow Point (JHP): JHP bullets have a hollow cavity in the tip, which expands upon impact, increasing stopping power. They are often preferred for self-defense and hunting.

- Soft Point (SP): Soft point bullets have a soft lead core exposed at the tip, offering a balance between penetration and expansion. They are popular for hunting medium to large game.

- Ballistic Tip: Ballistic tip bullets feature a plastic tip that improves aerodynamic performance. They combine the benefits of both FMJ and JHP bullets.

Safety and Handling

When dealing with ammunition, safety is of utmost importance. Here are some essential safety guidelines:

- Always handle ammunition with care and follow the manufacturer’s instructions.

- Store ammunition in a cool, dry place, away from direct sunlight and out of reach of children.

- Do not mix different types or brands of ammunition, as this can lead to unsafe conditions.

- Regularly inspect your ammunition for any signs of damage or deterioration.

Conclusion

Bullet manufacturing is a complex and intricate process that requires precision and attention to detail. From selecting the right raw materials to assembling and testing the finished product, each step plays a crucial role in ensuring the reliability and performance of ammunition. Understanding the manufacturing process provides insight into the craftsmanship behind these essential components of the firearms industry. Whether you are a manufacturer, enthusiast, or simply curious, grasping the fundamentals of bullet manufacturing is an invaluable asset.

FAQ

How often should I inspect my ammunition for damage?

+It is recommended to inspect your ammunition regularly, especially if it has been stored for an extended period. Look for any signs of corrosion, swelling, or cracks in the casing. If you notice any issues, it is best to dispose of the ammunition safely and obtain new rounds.

Can I reload my own ammunition at home?

+Yes, reloading your own ammunition is a popular practice among firearms enthusiasts. However, it requires specialized equipment and knowledge to ensure safety and consistency. It is essential to follow proper reloading procedures and guidelines to avoid any accidents.

What are the benefits of using high-quality ammunition?

+Using high-quality ammunition offers several advantages. It provides consistent performance, ensuring accurate and reliable firing. Additionally, premium ammunition often features advanced designs, such as specialized bullet tips, which enhance penetration, expansion, and overall effectiveness.

Are there any environmental considerations when manufacturing bullets?

+Yes, the bullet manufacturing industry is increasingly focusing on sustainability and environmental impact. Many manufacturers are adopting eco-friendly practices, such as recycling brass casings and reducing waste. Some companies also offer lead-free ammunition options, which minimize the environmental hazards associated with lead-based bullets.